Founded in

Covered area

Manufacturing equipment

Number of employees

In the world of metal fabrication and construction, the choice of a fastener is a critical engineeri...

View MoreA stainless steel industrial furnace represents a pinnacle of precision and durability in thermal pr...

View MoreThe global metallurgical industry is currently witnessing a profound transformation as the demand fo...

View MoreIn the complex world of industrial manufacturing and construction, the significance of selecting the...

View MoreStainless Steel Self Drilling Screws for Metal Roofing When it comes to metal roofing projects, usin...

View MoreSelecting the right stainless steel metal washer is a critical decision that impacts the integrity, ...

View MoreIn modern mechanical equipment and engineering systems, the stable operation of various components depends on precise design and efficient protection measures. Especially under high load, high friction and harsh environmental conditions, the long-term use of equipment faces severe challenges. Although physical pressure and friction are common influencing factors, the corrosive effects of the external environment also pose a threat to the performance and life of the equipment that cannot be ignored. In order to effectively resist environmental erosion and protect the stability and durability of mechanical parts, Metal Washer, as an important auxiliary component, plays a vital role, especially in the function of preventing corrosion.

In many industrial applications, equipment not only has to withstand the challenges of internal mechanical pressure, but also faces complex factors in the external environment. For example, environmental factors such as humidity, marine climate, high temperature, and corrosive gases may cause corrosion, oxidation or other chemical reactions of equipment components. These external factors not only directly affect the strength and function of the components, but may also cause embrittlement of the material, making the structure of the connector no longer firm, and may even eventually lead to the overall failure of the equipment.

Corrosion usually starts with tiny defects on the metal surface and intensifies over time as external conditions change. Especially in humid or chemical-rich environments, metal materials are more likely to react with air, moisture or other corrosive substances, resulting in corrosion and oxidation. This corrosion not only affects the strength of the components, but may also cause equipment failure or shutdown. Therefore, how to effectively prevent corrosion becomes the key to ensuring the long-term stable operation of the equipment.

Metal Washer plays a vital role in corrosion prevention. As an intermediate isolation layer made of metal materials, metal washers can effectively prevent the external environment from directly corroding the connecting parts of the equipment. Through precise design, Metal Washer forms a barrier layer between the connectors to prevent the penetration of external factors such as moisture, chemical gases, and acidic substances, greatly reducing the damage of environmental factors to metal parts.

The anti-corrosion effect of metal washers first comes from the particularity of their materials. By selecting suitable metal materials, Metal Washer can work stably in a variety of harsh environments and has stronger corrosion resistance. For example, in environments with high temperature, humidity, chemicals and other influences, metal washers can effectively isolate moisture and harmful substances in the air, form physical isolation with the surface of the connector, and delay the corrosion process.

In a changing external environment, Metal Washer effectively reduces direct contact and penetration of air, moisture and chemicals by improving the contact quality between the connection surfaces, thereby extending the service life of the components. The presence of metal washers avoids frequent contact between threads and connection parts and prevents direct corrosion reactions on the metal surface. Whether in a humid environment or in an industrial environment full of corrosive gases, Metal Washer can play an isolating role and reduce the impact of external invasion on the connection parts.

The realization of this physical isolation effect depends on the structural design and material selection of the metal washer. By enhancing the sealing of the contact surface, the metal washer reduces the penetration of external corrosion sources and prevents the occurrence of chemical reactions. By effectively isolating corrosive substances in the external environment, the metal washer provides additional protection for the components, prolongs their service life and ensures the long-term operation of the equipment.

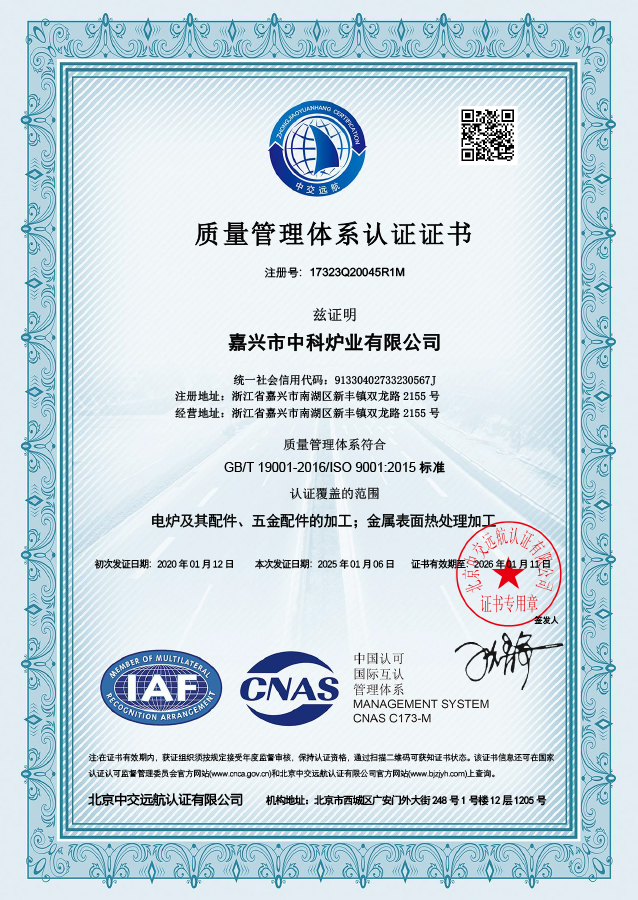

Jiaxing Zhongke Metal Technology Co., Ltd. is a manufacturer integrating the development, design and manufacturing of heat treatment equipment. Different working environments have different requirements for the corrosion resistance of metal washers. For marine environments, high temperature environments or chemical treatment environments, the material and design of metal washers must meet these special challenges. The material of Metal Washer can be customized according to different usage conditions to provide the best corrosion resistance.

For example, salt water in the marine environment is extremely corrosive to metal materials. Choosing metal materials with salt corrosion resistance can effectively prevent metal washers from being oxidized and corroded. In chemical processing sites, metal washers need to be resistant to strong acids and alkalis, and in high-temperature environments, the high-temperature resistance of washers will become an important factor in determining their effectiveness.

By selecting the right metal material, Metal Washer can maintain its excellent anti-corrosion performance in special working environments and ensure the long-term stable operation of the equipment. Customized metal washers not only meet the needs of different environments, but also improve the operating efficiency and safety of equipment under harsh conditions.