Founded in

Covered area

Manufacturing equipment

Number of employees

A Stainless Steel Industrial Furnace is a critical piece of equipment in modern manufacturing, espec...

View MorePrecision Engineering: Custom Stainless Steel Industrial Furnace for Heat Treatment In the high-prec...

View MoreIn the complex world of industrial manufacturing and construction, the integrity of an assembly is o...

View MoreIntroduction: The Backbone of Modern Fastening In the world of construction, manufacturing, and DIY ...

View MoreIn the world of metal fabrication and construction, the choice of a fastener is a critical engineeri...

View MoreA stainless steel industrial furnace represents a pinnacle of precision and durability in thermal pr...

View More1. The core role of bolt surface heat treatment process

The surface heat treatment process of stainless steel bolt is designed to improve the corrosion resistance and mechanical strength of bolts by changing the physical and chemical properties of the surface layer of the material. Common surface heat treatment processes include:

Carburizing treatment

The hardness and fatigue resistance are improved by infiltrating the surface of the bolt into carbon atoms. However, unprotected carburized layers tend to deteriorate corrosion resistance due to intergranular corrosion, so treatment is usually required in combination with other coatings.

Nitriding treatment

Nitriding treatment improves wear resistance and corrosion resistance by forming a dense layer of nitrogen compounds on the surface of the bolt. Compared with carburizing, the nitride layer has better corrosion resistance and is suitable for application in marine environments.

Annealing treatment

Annealing can eliminate internal stress of the material and improve the corrosion resistance of stainless steel bolts. Especially when residual stress is introduced during processing, annealing treatment is particularly important.

Electrochemical coating

Through the heat-treated electroless plating (such as nickel-phosphorus alloy coating), the anti-oxidation and acid-base corrosion resistance of the bolt surface can be greatly improved.

2. Specific impact of heat treatment process on corrosion resistance

Effect of heat treatment temperature on surface oxide film

During the heat treatment of stainless steel bolts, the formation of oxide film directly affects its corrosion resistance. If the heat treatment temperature is too high, it may lead to peeling or composition changes of the oxide film, thereby reducing its corrosion resistance. Therefore, during the heat treatment of stainless steel bolts, temperature control technology is usually used to ensure the stability of the oxide film.

Control of intergranular corrosion risk

Some stainless steel materials will produce intergranular carbide precipitation (such as Cr23C6) after high-temperature heat treatment, resulting in intergranular corrosion. By reducing the heat treatment temperature or using rapid cooling, the risk of intergranular corrosion can be effectively reduced.

The balance between surface hardness and corrosion performance

The risk of pitting corrosion may be increased while increasing the surface hardness after heat treatment. Therefore, the surface hardening treatment requires the incorporation of protective coatings to form a multi-layer corrosion-resistant barrier.

3. Industry case: Jiaxing Zhongke Metal Technology Co., Ltd.

As China's leading Custom Stainless Steel Bolt Manufacturers, Factory, Jiaxing Zhongke Metal Technology Co., Ltd. improves the corrosion resistance of bolt products through innovative heat treatment processes.

Digital production control

The company uses advanced MES system to monitor the heat treatment process in real time to ensure accurate control of the heat treatment temperature and time, and avoid degradation of corrosion resistance due to overheating or improper cooling.

Innovative material technology combination

Jiaxing Zhongke Metal Technology Co., Ltd. has developed a composite heat treatment process of "low-temperature carburizing + plating protection". By adding nickel-phosphorus alloy plating after carburizing, the corrosion resistance of the bolts is improved by 30%, especially suitable for high salinity environments.

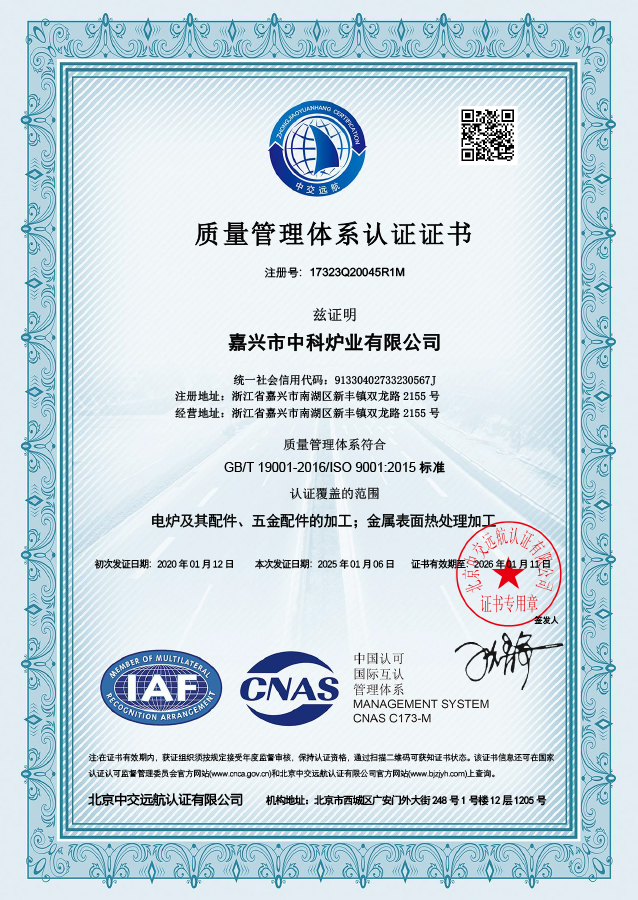

Full-chain quality management

Through the full-chain quality management system from raw materials to finished products, the company conducts multi-dimensional testing of the corrosion resistance of bolts (including salt spray testing and electrochemical corrosion testing) to ensure that the products meet customers' application needs in harsh environments.

With the improvement of fastener requirements in new energy, marine engineering and other fields, the bolt surface heat treatment process is developing towards compounding, intelligence and greening. Composite processes (such as carburizing + plating) achieve multiple protection through synergistic effects; intelligent control systems (such as PLC precision temperature control) improve process stability; low-temperature nitriding, chromium-free passivation and other technologies respond to environmental protection regulations and reduce heavy metal pollution.