ZKL Series 650℃ Box Tempering Furnace

Cat:Industrial Furnace

ZKL series 650℃ box-type tempering furnace is suitable for heat treatment proces...

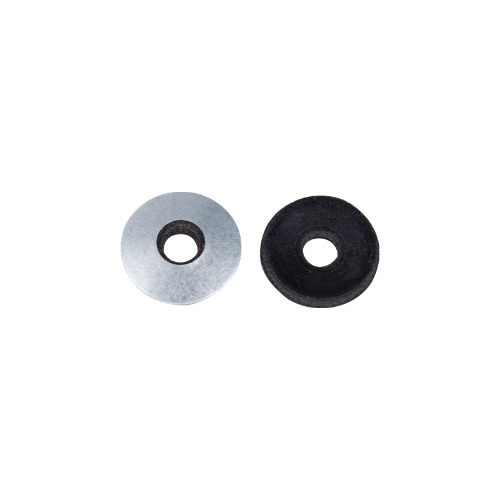

See DetailsIn scenarios requiring sealing and waterproofing—such as industrial equipment, pipeline connections, and household hardware—washers serve as core accessories, and their performance directly impacts the overall sealing effect and service life. Stainless steel waterproof washers have gradually become the first choice for numerous scenarios due to the dual advantages of their material and structure. In terms of material, stainless steel itself boasts excellent rust resistance; compared to ordinary carbon steel washers, it can be used for a long time in complex environments like humidity, acid, and alkali without easy oxidation or deformation. Meanwhile, the waterproof design, through special cross-sectional structures (such as corrugated shapes and raised edges), enhances the fit with connecting parts, effectively blocking the leakage path of water, gas, or liquid. Additionally, the high-strength characteristic of stainless steel allows the washer to maintain shape stability even under long-term pressure, avoiding seal failure caused by deformation. Whether for high-pressure sealing of industrial pipelines or daily waterproofing of household faucets, stainless steel waterproof washers can balance reliability and durability, which is the key reason for their prominence in the sealing accessory market.

The application range of stainless steel waterproof washers covers multiple fields, and the installation details in different scenarios directly affect their sealing effect. In industrial pipeline connection scenarios, they are often used at flange interfaces and need to be evenly tightened with bolts to ensure the washer fits perfectly with the flange surface, preventing gap leakage due to uneven local stress. During installation, it is necessary to clean impurities and oil stains on the interface surface to avoid foreign objects affecting the tightness of the sealing surface. In the field of household hardware, such as the connections of faucets and showers, stainless steel waterproof washers need to be selected according to the interface size. There is no need to over-tighten during installation, as excessive compression of the washer may cause it to lose elasticity, thereby reducing the waterproof effect. In outdoor equipment scenarios (such as solar water heater pipelines and outdoor lamp junction boxes), the impact of environmental temperature differences on the washer must be considered during installation. Stainless steel waterproof washers with a certain elastic coefficient should be selected to cope with the thermal expansion and contraction of connecting parts caused by temperature changes, maintaining long-term sealing performance.

There are significant differences in core performances such as sealing and durability between stainless steel waterproof washers and ordinary washers (such as rubber washers and carbon steel washers). In terms of sealing, the metal material and special structure of stainless steel waterproof washers can form a double sealing barrier, which not only blocks the leakage of liquid water but also resists gas leakage under a certain pressure. However, ordinary rubber washers tend to age and harden after long-term use, leading to a decrease in the fit of the sealing surface and an increased risk of leakage. In terms of durability, the rust resistance of stainless steel waterproof washers is far superior to that of carbon steel washers. In humid or acid-alkali-containing environments, carbon steel washers may rust within a few months, while stainless steel waterproof washers can maintain stable performance for several years or even longer. Furthermore, in high-temperature scenarios (such as hot water pipelines and mechanical equipment heat dissipation ports), the high-temperature resistance of stainless steel waterproof washers is significantly better than that of ordinary rubber washers. They will not soften and deform due to high temperatures, ensuring the sealing effect is not affected by temperature.

To determine the corrosion resistance of stainless steel waterproof washers, scientific testing methods are required to verify their tolerance in complex environments. A common testing method is the salt spray test: the washer is placed in a salt spray chamber simulating a marine environment, and a certain concentration of saltwater is continuously sprayed. The surface of the washer is observed for rust, spots, or oxidation marks within a specified time. High-quality stainless steel waterproof washers can usually maintain an intact surface in a salt spray test of more than 500 hours. Another commonly used method is the acid-base immersion test: the washer is immersed in acidic (such as 3% hydrochloric acid solution) and alkaline (such as 5% sodium hydroxide solution) environments respectively. After a period of time, the weight change, dimensional deformation, and sealing performance of the washer are measured. If the weight loss rate is less than 1%, the dimensional change rate is less than 0.5%, and there is no significant decline in sealing performance, it indicates that its corrosion resistance meets the standard. In addition, in actual use scenarios, the corrosion resistance can also be indirectly determined by regularly observing whether the washer surface has discoloration or rust, or by detecting whether there is leakage at the sealing part.

The accuracy of size and model selection for stainless steel waterproof washers directly determines the sealing effect and installation adaptability. First, it is necessary to clarify the interface parameters of the connecting parts, including core data such as bolt diameter, interface aperture, and sealing surface width. For example, for a connecting part with a bolt diameter of M10, a washer with an inner diameter slightly larger than M10 (usually 0.5-1mm larger) and an outer diameter determined according to the width of the sealing surface should be selected. This ensures the washer can fully cover the sealing area without exceeding the interface range. Second, the model should be selected according to the pressure and temperature requirements of the use scenario. For high-pressure scenarios, thickened stainless steel waterproof washers (usually 2-5mm in thickness) should be selected; for high-temperature scenarios, washers made of stainless steel with a higher nickel content (such as 316 stainless steel) should be chosen to enhance high-temperature stability. In addition, attention should be paid to the cross-sectional shape of the washer. For example, flat washers are suitable for flat sealing surfaces, while corrugated washers are suitable for slightly uneven sealing surfaces. The selection should be based on the actual flatness of the sealing surface to avoid seal failure due to mismatched shapes.

Daily maintenance can effectively extend the service life of stainless steel waterproof washers, and timely identification of aging signs can prevent failures caused by seal failure. In terms of maintenance, for stainless steel waterproof washers in long-term use, it is necessary to regularly check whether there is leakage at the sealing part and whether there is dirt accumulation on the washer surface. If leakage is found, it is necessary to first determine whether it is due to washer aging or loose installation. If the poor fit of the sealing surface is caused by dirt, the washer surface and sealing surface can be cleaned with a neutral detergent after disassembly, and then reinstalled after drying. If there are slight scratches on the washer surface, a small amount of sealant can be applied to enhance the sealing performance. Aging identification can be done by combining sensory and performance testing: visually observe whether the washer surface has cracks, deformation, or rust spots; tactilely press the washer to feel its elasticity—if it cannot rebound quickly after pressing, it indicates a decrease in elasticity. In terms of performance, a pressure test can be conducted to check whether the sealing part leaks under the specified pressure. If the leakage exceeds the standard range, it indicates that the washer has aged and needs to be replaced in a timely manner.