Monomer gaskets and conjoined gaskets are two types of sealing materials widely used in industry and daily life, with different characteristics and uses.

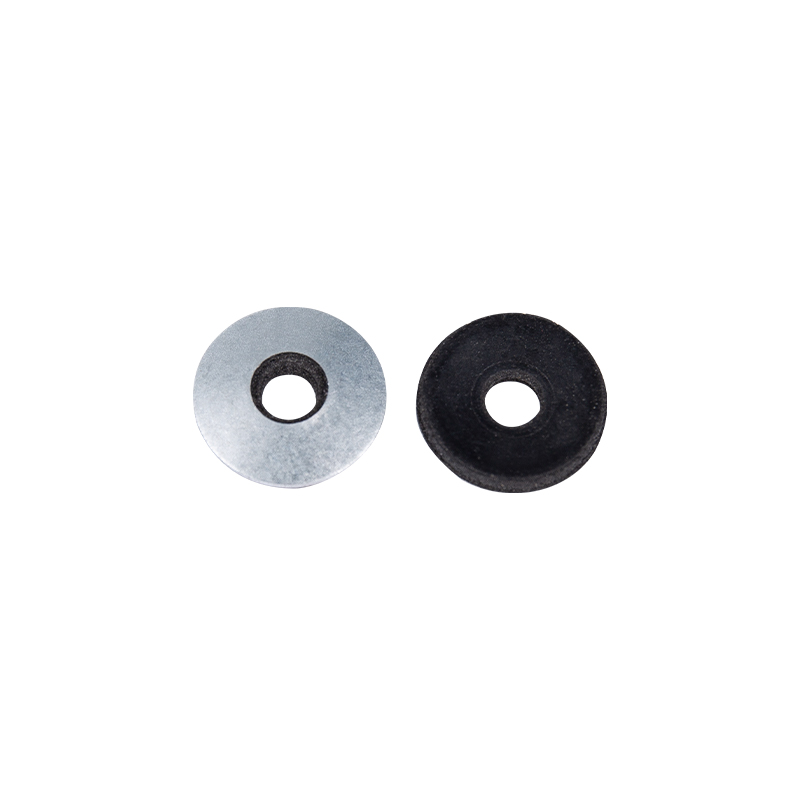

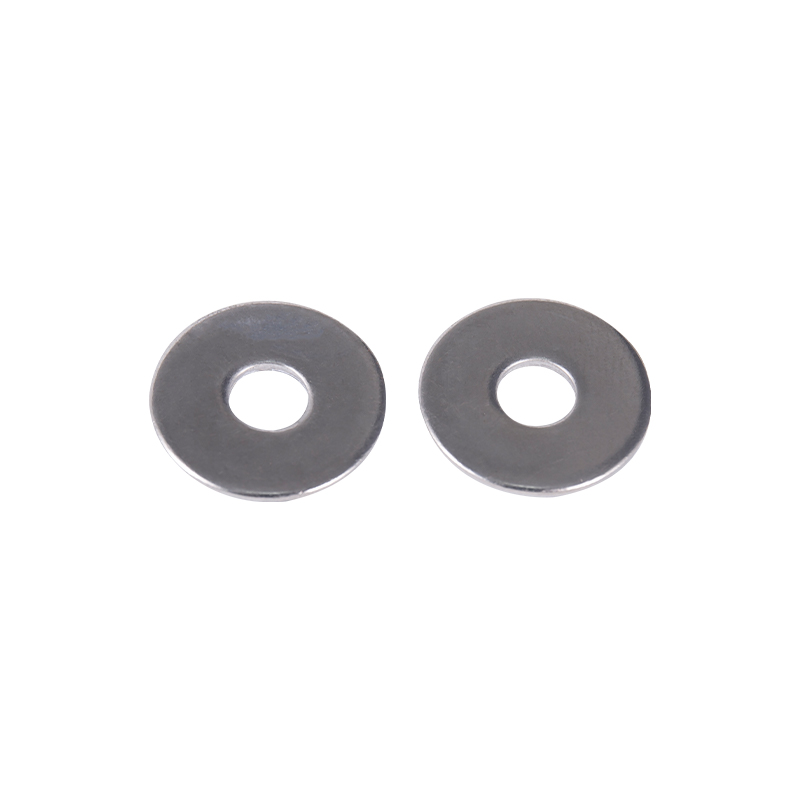

Monomer gaskets are independent sealing elements, usually made of rubber, PTFE (polytetrafluoroethylene) or other high temperature and corrosion resistant materials. They are characterized by simple structure and easy installation, and are suitable for flange connections of various mechanical equipment. They have excellent chemical resistance and sealing performance, and are widely used in chemical, petroleum, factory equipment and other fields, with a maximum operating pressure of up to 1.0MPa. Monomer gaskets are also widely used in industrial pipelines, valves and other scenes because of their mature processing technology and low cost.

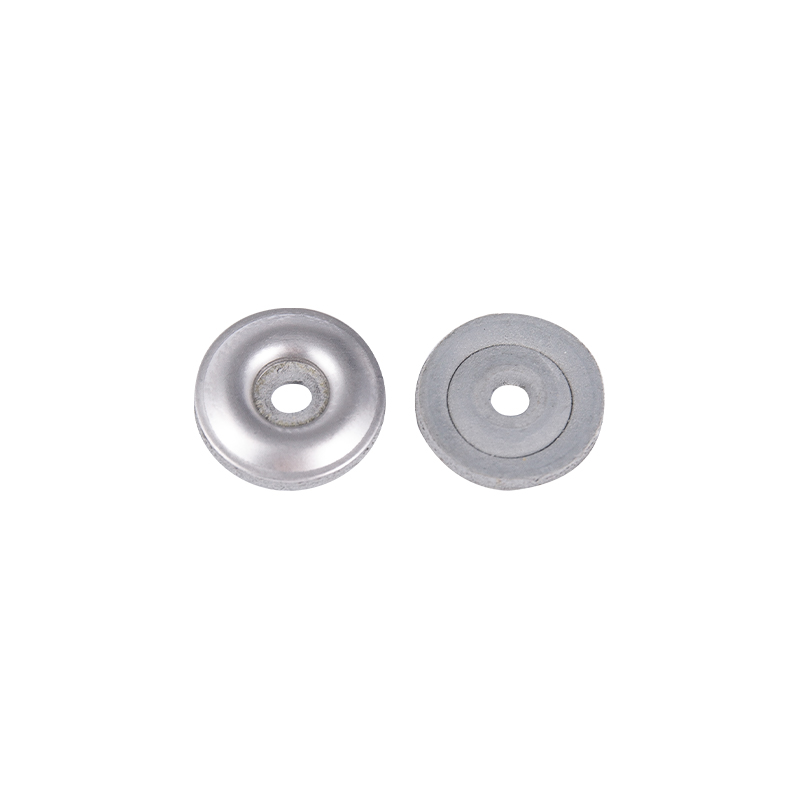

Conjoined gaskets are an integral structure composed of multiple separate sealing units, which are usually used in occasions requiring higher sealing performance. They are mainly used in transportation facilities and industrial equipment. Through optimized design, conjoined gaskets can effectively fill the small gaps between the connection surfaces, thereby improving the sealing effect and extending the service life. Its production process includes steps such as rubber refining, vulcanization, and molding, ensuring the high quality and consistency of the product.

English

English Español

Español عربى

عربى