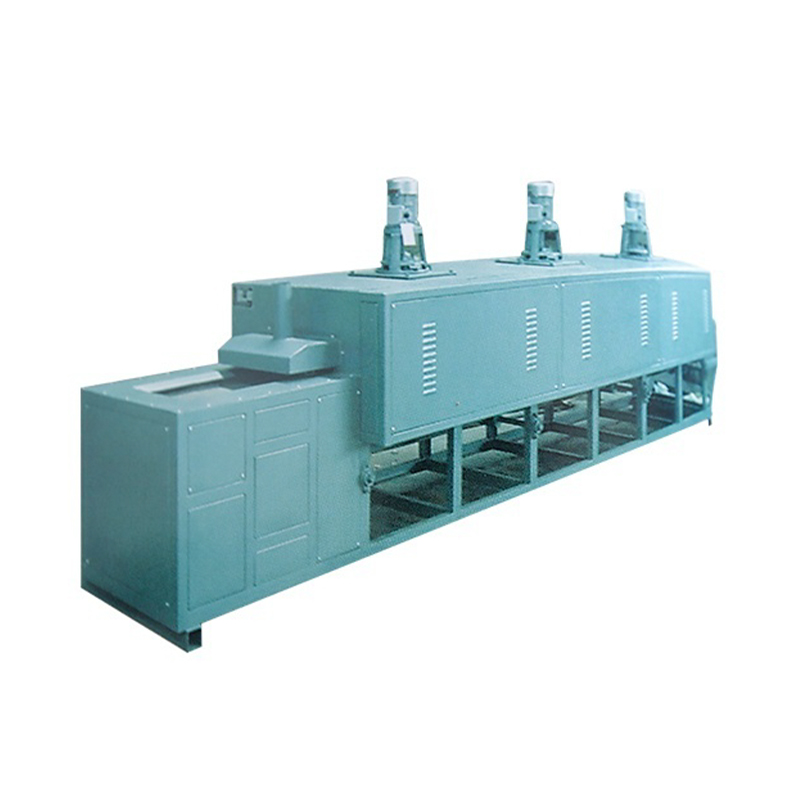

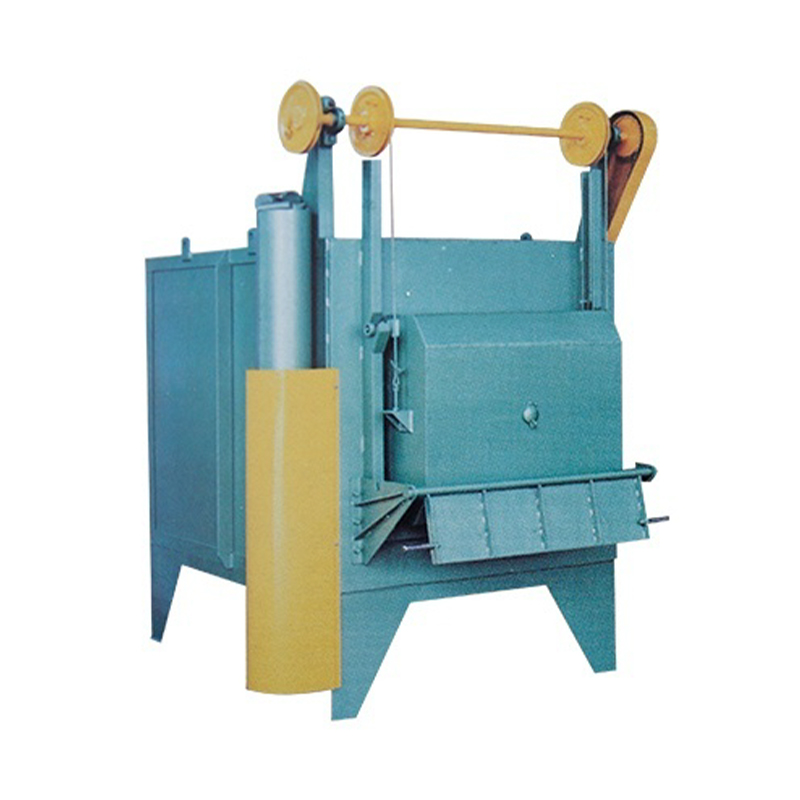

The ZKL series continuous mesh belt conveyor tempering furnace is suitable for batch tempering of various small and medium-sized metal parts. The equipment uses a mesh belt woven with high-strength stainless steel wire as a conveying carrier, and realizes uniform heating and tempering of the workpiece through a temperature-controlled heating zone. It is widely used in the heat treatment process of parts such as springs, bearings, standard parts, small hardware, and textile parts.

The core advantage of the ZKL series tempering furnace lies in its advanced design and technical configuration. The furnace body adopts a full-fiber structure, has good thermal insulation performance, fast heating and low energy consumption, and the maximum temperature can reach 650℃. At the same time, it is equipped with a PID intelligent temperature control system to ensure the stability of the tempering process and the consistency of the workpiece quality. The equipment is also equipped with a large impeller forced circulation fan to improve the heat transfer efficiency and make the furnace temperature more uniform, thereby improving production efficiency.

The transmission system of the ZKL series equipment is simple and reliable, and the mesh belt speed can be adjusted steplessly to meet different process requirements. During operation, the electric heating element can be replaced without disassembling the furnace body, which is convenient for maintenance. The overall structure of the equipment is compact, and it can be combined with a mesh belt quenching furnace, a cleaning machine, etc. to form an automated production line to further improve production efficiency.

Ordinary nuts Flange nuts Lock nuts

Cat:Nuts

Ordinary nuts, flange nuts and anti-loosening nuts are three common fasteners, each with unique design features and application scenarios.Ordinary nut...

See Details

English

English Español

Español عربى

عربى