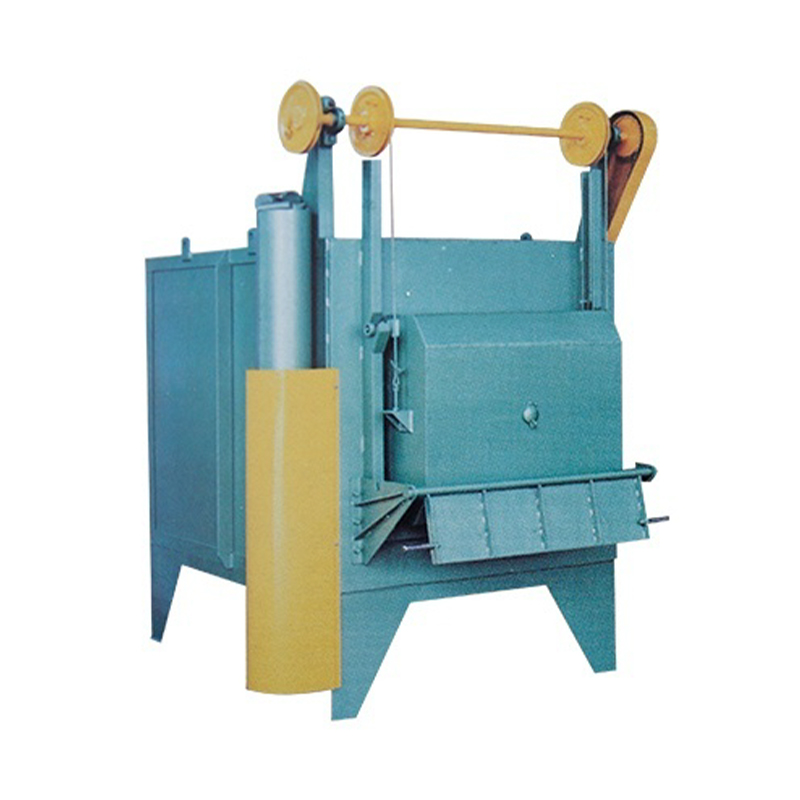

The ZKL series 950℃ rotary resistance furnace adopts advanced design concepts, combines the characteristics of energy saving and high efficiency, and is widely used in heat treatment processing in the fields of metal materials, alloy steel parts and chemical materials.

The core features of the ZKL series resistance furnace include:

Rated temperature up to 950℃: The maximum temperature of the furnace can reach 950℃, which can meet the quenching, tempering, annealing and other process requirements of various metal materials and alloy steel parts, and is also suitable for special heat treatment of ceramic materials and chemical materials.

Reasonable structural design: The furnace body is sintered by refractory materials, and the furnace lining is a combination of lightweight refractory bricks and insulation materials, which has good insulation performance and can effectively reduce energy consumption.

Intelligent control system: Equipped with microcomputer intelligent instrument, supports PID automatic temperature control, and has over-temperature alarm function, which is easy to operate.

Safe and reliable: The furnace door adopts roller guide design to ensure sealing while avoiding friction damage; the mechanical transmission method is stable and reliable, and has a long service life.

Wide range of applications: It can handle a variety of industrial materials such as aluminum molds, steel molds, and molds, and is also suitable for heat treatment of new materials such as lithium iron phosphate materials and rare earth materials.

ZKL Series 550℃ Thermal Cycle Oven

Cat:Industrial Furnace

The ZKL series 550℃ thermal cycle oven is a high-performance industrial drying equipment suitable for a variety of industrial and laboratory scenarios...

See Details

English

English Español

Español عربى

عربى