Ordinary nuts, flange nuts and anti-loosening nuts are three common fasteners, each with unique design features and application scenarios.

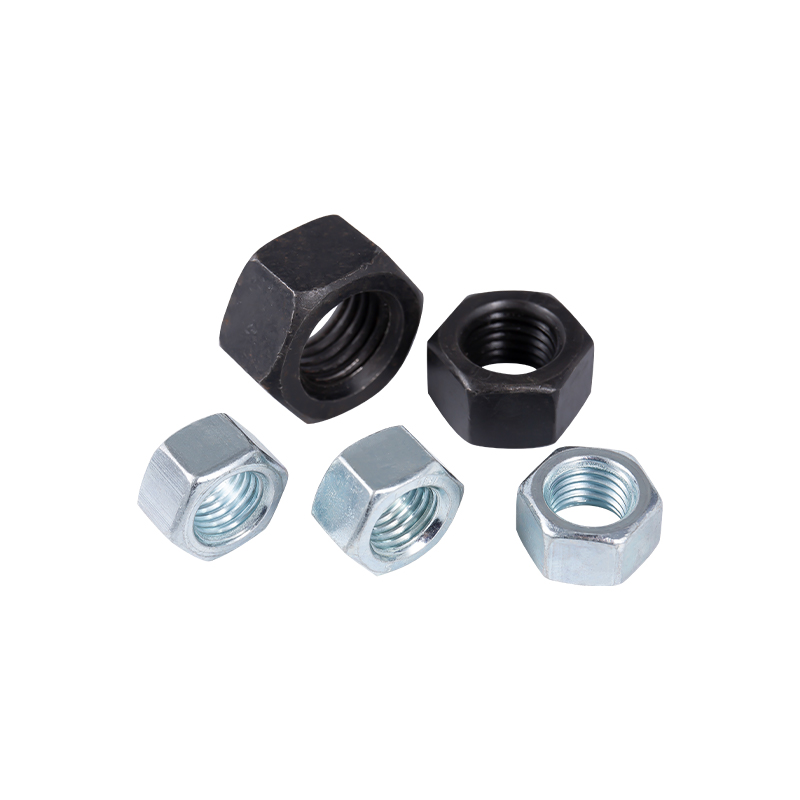

Ordinary nuts are a basic fastener, mainly used to connect two or more parts to ensure their stability and safety. Ordinary nuts usually adopt a standard hexagonal shape, have high tensile strength, and are suitable for fixing general mechanical structures. Due to their simple structure, ordinary nuts are easy to loosen under vibration or force, so they need to be used with auxiliary components such as washers.

Flange nuts are a specially designed nut, the main feature of which is that they have a flange plate at the bottom, which can be used in combination with gaskets to increase the contact area and improve the stability of the connection. Flange nuts are widely used in pipeline connections, valve fixation, and industrial equipment that requires additional contact surfaces. The design of flange nuts enables them to withstand high pressure and high temperature environments, while having good sealing performance. Flange nuts are also divided into two types: with anti-loosening pattern teeth and without pattern teeth. Flange nuts with pattern teeth evenly disperse pressure through tooth pattern distribution to effectively prevent loosening.

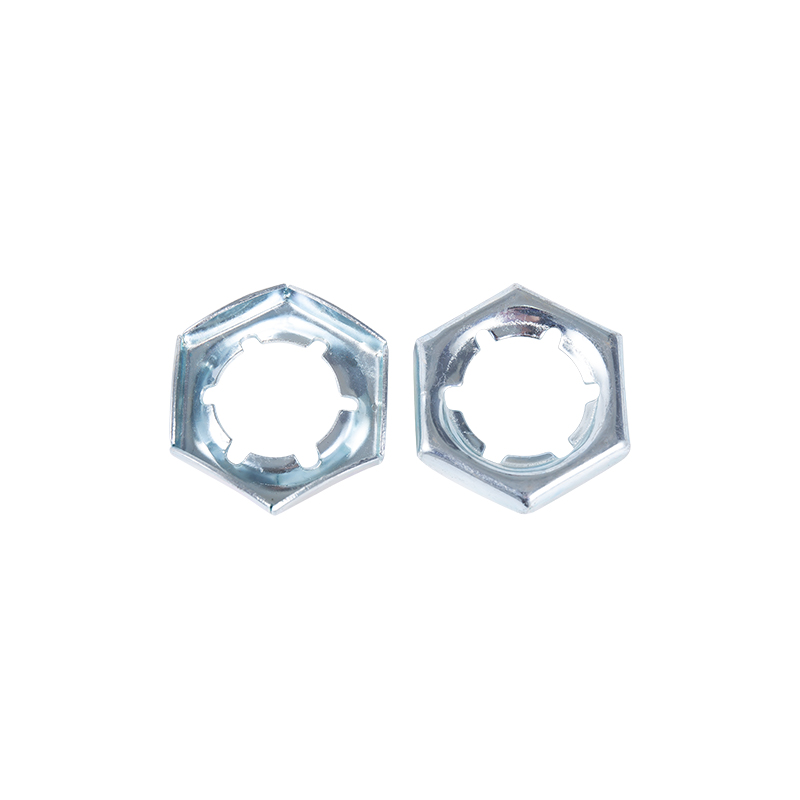

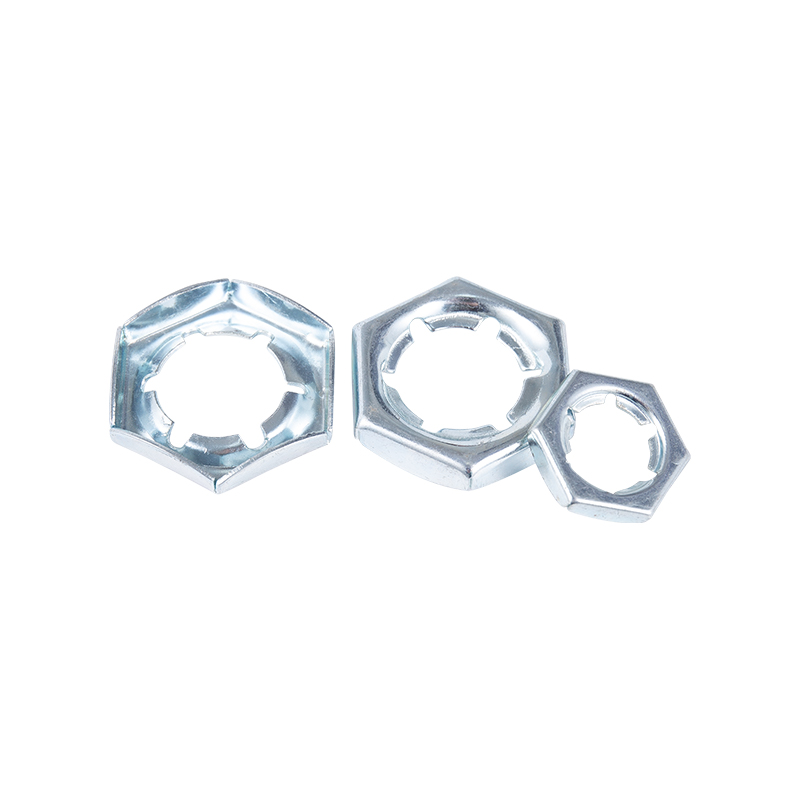

Anti-loosening nuts are a fastener specially designed to prevent threaded connections from loosening. Anti-loosening nuts usually adopt special structural designs, such as double-tooth type, wedge-shaped thread or self-locking function, to improve anti-loosening performance. For example, the double variable tooth anti-loosening nut can maintain a reliable anti-loosening effect under the influence of temperature changes or acid-base environment through a unique thread design. Anti-loosening nuts are also commonly used in occasions that require frequent disassembly and assembly, such as automotive parts, mechanical equipment, etc., and their anti-loosening performance is significantly better than ordinary nuts.

Ordinary nuts are suitable for general scenarios, flange nuts are suitable for pipe or equipment connections that require increased contact area, and anti-loosening nuts are suitable for occasions with higher anti-loosening performance requirements. The selection of the appropriate nut type needs to be matched according to the specific application requirements, working environment and standard specifications to ensure the reliability and safety of the connection.

ZKL Series 950℃ Rotary Resistance Furnace

Cat:Industrial Furnace

The ZKL series 950℃ rotary resistance furnace adopts advanced design concepts, combines the characteristics of energy saving and high efficiency, and ...

See Details

English

English Español

Español عربى

عربى