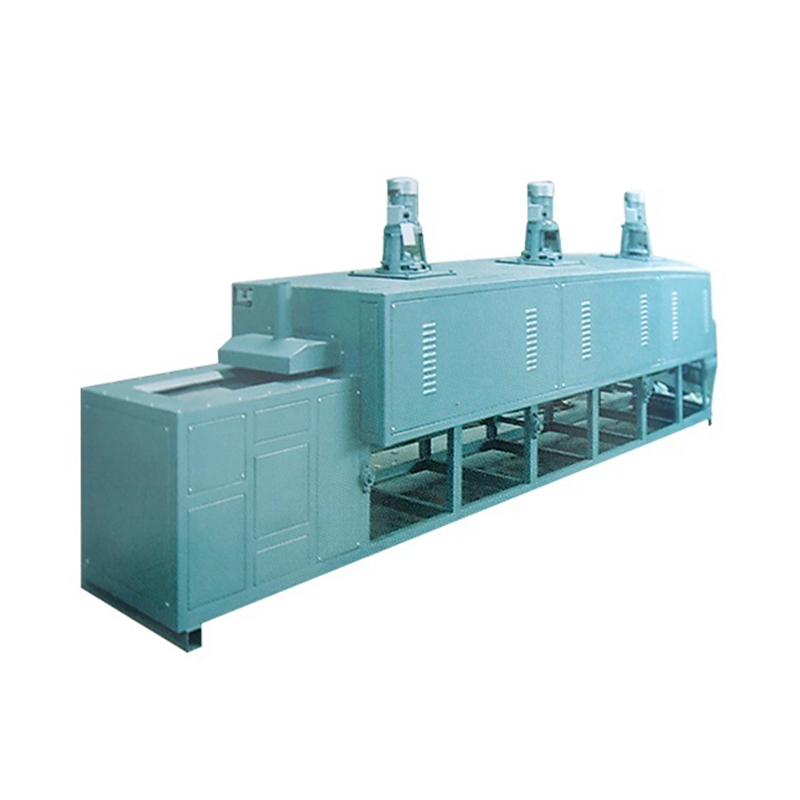

The ZKL series 650℃ pit-type gas nitriding furnace is specially designed for surface heat treatment of metal parts. It is suitable for gas nitriding and soft nitriding of steel mechanical parts, automobile crankshafts, piston rings, motorcycle brake pads and molds. The equipment has a maximum operating temperature of 650℃. It adopts advanced energy-saving design and automatic control system, which can achieve precise temperature control and uniform atmosphere distribution, thereby significantly improving the quality and efficiency of nitriding treatment.

The furnace body has a compact structure and is welded with high-temperature resistant alloy steel. The furnace lining is composed of lightweight refractory materials and thermal insulation materials, which ensures the durability and thermal insulation performance of the equipment. The furnace cover is lifted by an electric hydraulic device, which is stable, safe and reliable in operation. At the same time, it is equipped with a rapid cooling system, which can greatly shorten the production cycle.

The hot air circulation device ensures the uniformity of the atmosphere and temperature in the furnace, avoiding deformation and oxidation of the workpiece; the double-layer sealing design improves the sealing of the atmosphere in the furnace and extends the service life of the nitriding layer; the vacuum exhaust system and automatic temperature control function further improve the stability and environmental benefits of the nitriding process.

Pan Head Self-Drilling Screws

Cat:Self Drilling Screws

Pan Head Self-Drilling Screws are a type of fastener widely used in construction, furniture, billboards and industrial equipment. They have self-drill...

See Details

English

English Español

Español عربى

عربى