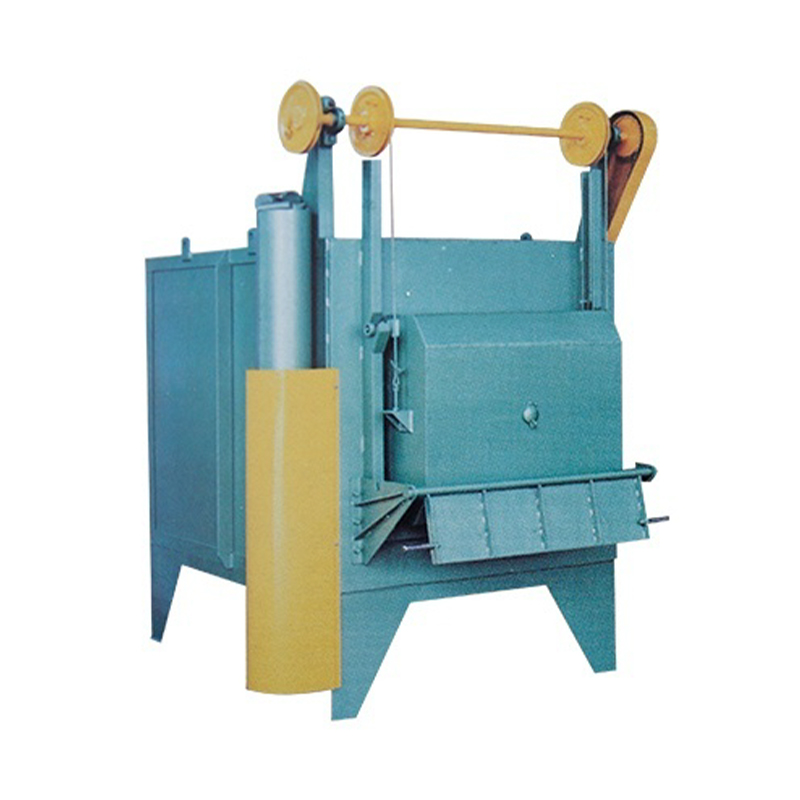

RX3 series box-type resistance furnaces are widely used in the field of metal heat treatment, including normalizing, annealing, quenching, tempering and sintering processes. Its design structure is reasonable, with a furnace shell welded from high-quality steel plates and angle steels, and filled with refractory insulation materials such as aluminum silicate fiber and expanded graphite powder, which ensures good insulation performance and energy saving effects.

The rated temperature range of this series of resistance furnaces is 950℃ to 1200℃, which is suitable for heat treatment of general metal parts, mold steel, alloy steel and other materials. Its heating element is a spiral wound with high-resistance alloy wire, which is installed on the two walls of the furnace and the shelf bricks. It heats up quickly and evenly, and the temperature difference is controlled within ±2℃, which meets the needs of precision heat treatment.

The RX3 series resistance furnace has a variety of models to choose from to meet the needs of production of different scales. Its control system adopts intelligent microcomputer adjustment technology, supports PID temperature automatic adjustment, and is equipped with over-temperature alarm function to ensure safe and reliable operation.

This series of resistance furnaces also supports simple protective atmosphere devices, which can reduce oxidation losses and is suitable for heat treatment scenarios with special process requirements. The outer shell has good sealing performance, and the furnace door is raised and lowered with a roller guide design, which is easy to operate and has good sealing performance.

ZKL Series 850℃ Crucible Melting Resistance Furnace

Cat:Industrial Furnace

ZKL series 850℃ pre-vacuum aluminum fiber welding resistance furnace is a high-efficiency equipment designed for aluminum processing and precision wel...

See Details

English

English Español

Español عربى

عربى