Machine screws are fasteners designed to be used with pre-threaded holes or nuts, relying on existing threads for fastening.

Key features:

Precision Threading: Manufactured with exact thread dimensions to ensure perfect mating with pre-threaded holes or nuts

Structural Integrity: Stable thread structure allows repeated assembly/disassembly without causing thread damage

Typical applications:

Optical equipment and internal clockwork mechanisms (requiring small-diameter screws such as M1.2)

Circuit board mounting and enclosure assembly (commonly using M2-M4 sizes with surface insulation treatment)

Gearbox and transmission component connections (utilizing high-strength alloy steel screws)

Engine accessories and interior trim installation (incorporating vibration-proof and locking designs)

Founded in

Covered area

Manufacturing equipment

Number of employees

A Stainless Steel Industrial Furnace is a critical piece of equipment in modern manufacturing, espec...

View MorePrecision Engineering: Custom Stainless Steel Industrial Furnace for Heat Treatment In the high-prec...

View MoreIn the complex world of industrial manufacturing and construction, the integrity of an assembly is o...

View MoreIntroduction: The Backbone of Modern Fastening In the world of construction, manufacturing, and DIY ...

View MoreIn the world of metal fabrication and construction, the choice of a fastener is a critical engineeri...

View MoreA stainless steel industrial furnace represents a pinnacle of precision and durability in thermal pr...

View More1. Precision Thread Machining: Enhancing Accuracy for Optimal Assembly

The threading system of machine screws serves as a "precision mechanical language," ensuring secure and reliable connections through standardized geometric parameters. Precision thread machining focuses on achieving a seamless fit between screws and prefabricated thread holes by maintaining key tolerances, such as pitch, tooth angle, and diameter, to micron-level accuracy (e.g., ±0.005mm). This precision delivers three critical benefits:

Seamless Mechanical Occlusion

For applications like optical devices, where misalignment due to thread errors can compromise system performance, precision threading ensures "gapless conduction." For instance, in M1.2 micro-screws, controlling thread errors to within ±0.008mm maintains the stability of optical systems.

Dynamic Load Resistance

High-strength machine screws, such as those used in gearboxes, benefit from precise grinding techniques that reduce stress concentration. Precision threading can improve the fatigue life of mechanical connections by over 40%, significantly reducing maintenance costs.

Durability in Repeated Assemblies

Machine screws, such as spark plug screws in automotive engines, often undergo multiple disassembly and reassembly cycles. Precision threading ensures these screws retain their structural integrity and resist wear, even after 50+ cycles, due to accurate control of surface hardness and wear resistance.

2. Adaptability Across Industries: The Versatility of Machine Screws

Precision threading technologies adapt to the unique requirements of various industries, tailoring machine screws for specific performance demands.

Electronics: Precision and Insulation

In electronic devices, machine screws must ensure both precise threading and surface insulation. Techniques like electroless nickel-phosphorus plating achieve insulation resistance (≥10^9Ω) without compromising thread accuracy, overcoming challenges like "plating accumulation" that can cause locking issues.

Heavy Machinery: Material and Process Coordination

Machine screws for heavy machinery, such as those in gearboxes, require meticulous control of thread diameters (±0.015mm) and robust materials like 42CrMo alloy steel. Using advanced tools and techniques, these screws withstand axial loads exceeding 20 tons after tempering.

Aerospace: Performance in Extreme Environments

Aerospace-grade machine screws crafted from titanium alloys undergo cold-work hardening to form a durable surface layer. This process enhances fatigue strength by 60% compared to traditional methods and ensures resilience against temperature fluctuations from -196°C to 300°C.

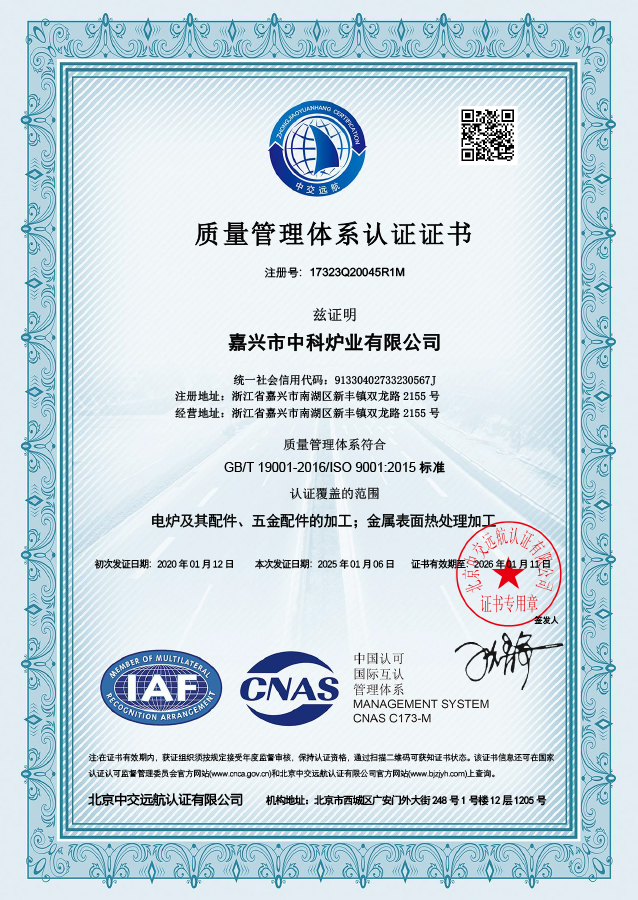

3. Industry Excellence: Jiaxing Zhongke Metal Technology Co., Ltd.

As a leading Machine Screws factory, Jiaxing Zhongke Metal Technology Co., Ltd. exemplifies innovation in precision machining. The company integrates cutting-edge technologies to deliver exceptional results:

Digital Production and Full-Chain Control

Jiaxing Zhongke employs UG software for thread simulation and an MES system for real-time data collection, achieving unparalleled traceability with accuracy up to 0.001mm.

Material Process Innovation

The company has developed a "low-temperature milling + ultrasonic vibration" composite process for machining 316L stainless steel machine screws. This approach improves thread processing efficiency by 1.8x and reduces surface roughness by 50%, meeting stringent medical device standards.

Customized Solutions for Diverse Applications

With the capability to manufacture both standard and non-standard machine screws, including Imperial UNF and Wyeth threads, Jiaxing Zhongke offers rapid prototyping within 48 hours and serves high-end manufacturing clients in over 20 countries.

4. Future Trends: Intelligent Precision Threading of Machine Screws

As Industry 4.0 reshapes manufacturing, precision threading of machine screws is evolving through smart technologies:

AI-Driven Optimization

Machine learning algorithms analyze machining data to generate optimal cutting parameters, improving thread processing yield from 95% to 98.7%.

Real-Time Online Detection

AI-integrated machining centers perform full-parameter thread scans within 0.1 seconds, adjusting machine tool parameters instantly for zero-defect production.

Additive Manufacturing Integration

Combining selective laser melting (SLM) with precision turning enables the creation of complex, variable-pitch threads for advanced applications like aircraft engines, while boosting material utilization to over 95%.