Countersunk machine screws are widely used in machinery, furniture, electronics and construction. Their design feature is that the head sinks into the surface of the workpiece, thus achieving a beautiful and firm connection effect. This product has a variety of specifications and surface treatment methods to meet the needs of different scenarios.

Countersunk machine screws comply with international standards DIN965, ISO 7046 and ANSI/ASME B18.6.3, ensuring the versatility and reliability of the product. In terms of materials, a variety of options are available, including SUS410, SUS304, SUS316 stainless steel and carbon steel, among which stainless steel models (such as 304, 316) have excellent corrosion resistance and are suitable for humid or chemically corrosive environments.

The specifications cover a wide range, from M3 to M8, and sizes from 6# to 1/4", which can meet the fixing needs of materials of different thicknesses. In terms of surface treatment, passivation, galvanizing, nickel plating, blackening, head spraying, Dacromet, hot rust and other processes are provided to enhance corrosion resistance or meet specific appearance requirements.

These countersunk machine screws adopt precision processing technology to ensure high thread accuracy and reliable strength, and the head design meets standard requirements, which can effectively prevent loosening.

Whether it is used for furniture assembly, mechanical equipment fixing or architectural decoration, countersunk machine screws have become an indispensable fastener solution for modern industrial and home life with their diverse specifications, reliable performance and flexible surface treatment options.

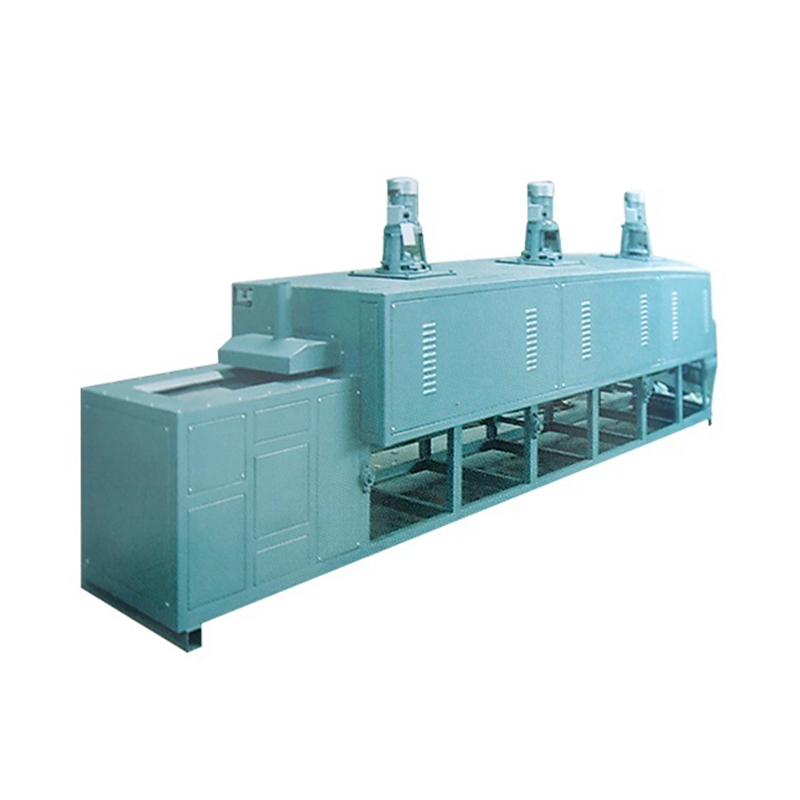

ZKL Series 950℃ Rotary Resistance Furnace

Cat:Industrial Furnace

The ZKL series 950℃ rotary resistance furnace adopts advanced design concepts, combines the characteristics of energy saving and high efficiency, and ...

See Details

English

English Español

Español عربى

عربى