Founded in

Covered area

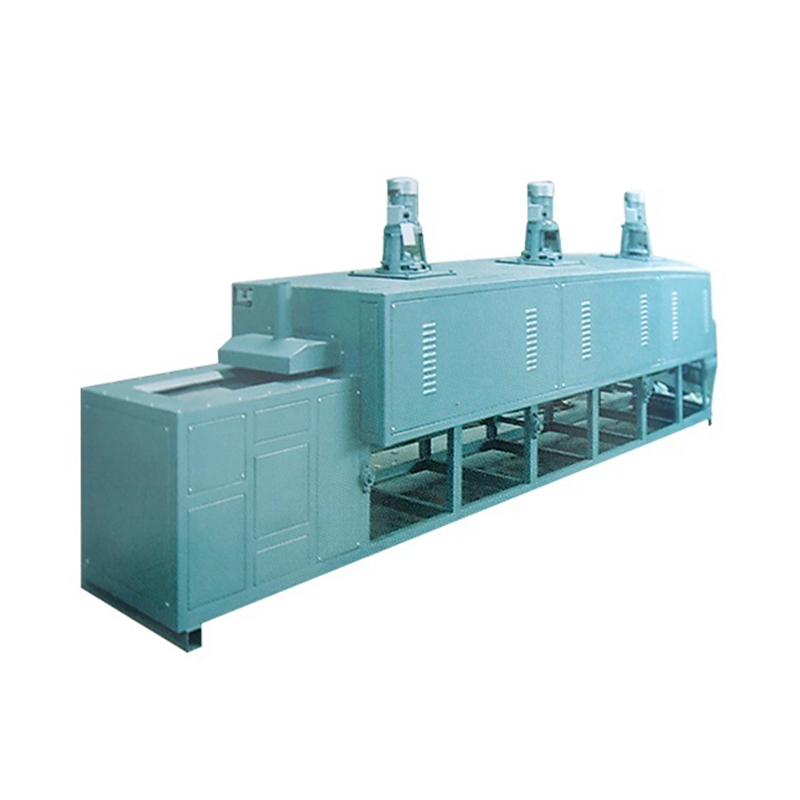

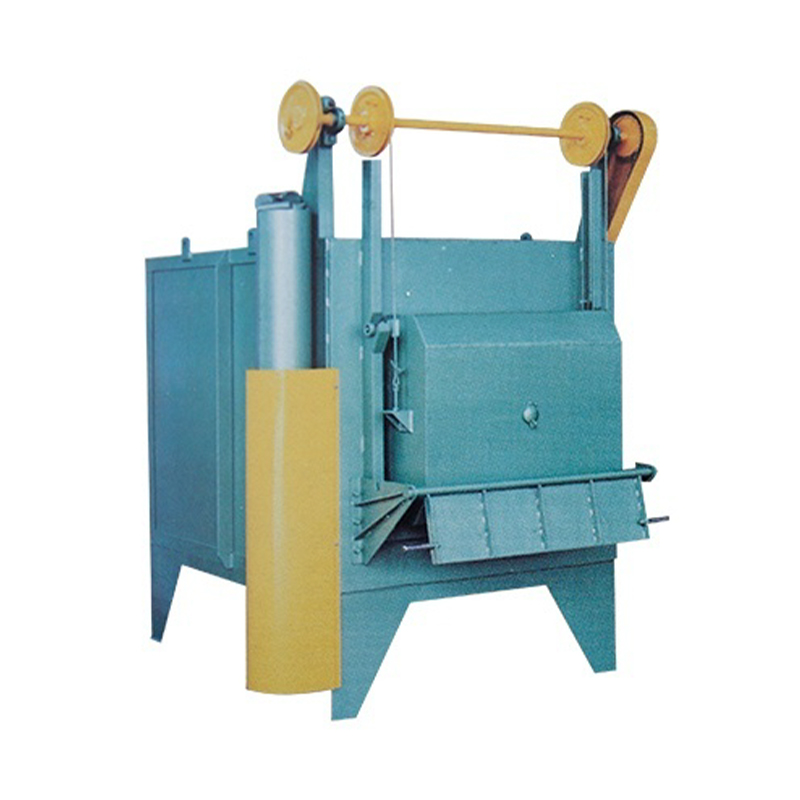

Manufacturing equipment

Number of employees

A Stainless Steel Industrial Furnace is a critical piece of equipment in modern manufacturing, espec...

View MorePrecision Engineering: Custom Stainless Steel Industrial Furnace for Heat Treatment In the high-prec...

View MoreIn the complex world of industrial manufacturing and construction, the integrity of an assembly is o...

View MoreIntroduction: The Backbone of Modern Fastening In the world of construction, manufacturing, and DIY ...

View MoreIn the world of metal fabrication and construction, the choice of a fastener is a critical engineeri...

View MoreA stainless steel industrial furnace represents a pinnacle of precision and durability in thermal pr...

View MoreIn today’s industrial landscape, the demand for precise, durable, and high-performance components is ever-growing. Industries like automotive manufacturing, aerospace, electronics, and materials science all rely heavily on the ability to withstand extreme temperatures during production and processing. This is where industrial high-temperature resistance furnaces come into play. These furnaces, engineered to operate at extremely high temperatures, have become indispensable tools for various sectors.

The Role of High-Temperature Resistance Furnaces in Heat Treatment

Heat treatment is a crucial process in the manufacturing of components, particularly metals and alloys, as it helps to improve their properties such as strength, hardness, and durability. High-temperature resistance furnaces are specifically designed to reach the necessary temperatures required for various heat treatment processes, which can range from 500°C to over 2000°C, depending on the material and application.

The heat treatment process usually involves heating the material to a specific temperature and then cooling it rapidly or gradually to achieve the desired structural characteristics. High-temperature resistance furnaces ensure precise temperature control and uniform heating, ensuring that every part meets the required specifications. The ability to maintain such high temperatures consistently is a key feature that sets these furnaces apart from standard furnaces, making them indispensable in many advanced manufacturing processes.

Key Applications of High-Temperature Furnaces in Modern Industry

1. Automotive Industry: Enhancing Performance and Safety

In the automotive industry, the performance and safety of vehicles are paramount. Parts such as engine components, transmission systems, and exhaust systems often require high-temperature resistance furnaces for heat treatment processes like hardening, tempering, and annealing. These processes help to increase the strength, wear resistance, and fatigue resistance of materials.

2. Aerospace Industry: Precision and Reliability

The aerospace industry relies on components that must perform flawlessly even in the most extreme conditions. From turbine blades to landing gear, high-temperature resistance furnaces are vital for the heat treatment of critical aerospace components. These furnaces are used to treat superalloys, titanium, and other high-performance materials that are essential for ensuring the safety and efficiency of aircraft.

By using high-temperature furnaces, manufacturers can achieve the precise hardness and tensile strength required for components that are subjected to extreme forces, temperatures, and vibrations. The accuracy and consistency offered by these furnaces are indispensable for meeting the stringent standards in the aerospace industry.

3. General Manufacturing: Boosting Material Strength and Durability

Beyond the automotive and aerospace industries, high-temperature resistance furnaces are used extensively in general manufacturing. Whether it’s for producing steel, alloyed materials, or heat-resistant components, these furnaces provide the necessary temperature ranges for a wide variety of processes such as carburizing, nitriding, and quenching.

Jiaxing Zhongke Metal Technology Co., Ltd. not only serves the heat treatment industry but also develops and manufactures general parts that benefit from high-temperature resistance. Their innovative furnace systems are designed to improve the overall efficiency and consistency of material processing, contributing to the enhanced durability and quality of the final product.

One might wonder, with such high operating temperatures, aren’t these furnaces energy-intensive and costly to run? The answer is no—at least not with modern designs. Jiaxing Zhongke Metal Technology Co., Ltd. is energy efficiency. Newer models of high-temperature resistance furnaces are equipped with advanced insulation and energy-saving technologies, making them much more energy-efficient than their predecessors.

The use of advanced refractory materials and better heat retention systems reduces energy consumption and operating costs.Features such as programmable temperature controllers and automated monitoring systems help ensure that the furnaces only consume as much energy as necessary, further lowering operational expenses. This balance of high performance and energy efficiency is crucial for long-term cost savings in industrial production.